Feed part:

1. Positioning plate: adjust the positions of both ends to match the feed width

2. Guide rail frame: plays a role in supporting material roll transportation

3. Guide roller: the design of upper and lower round rollers makes the feeding process more smooth.

Get a free offer

xCollecting roof rainwater is an integral part of the falling water system, which is concentrated into the rainwater pipes laid below the ground. The steel downspout roll forming machine is used to produce downpipes for rainwater systems. The downspout making machine adopts new high-tech, owning higher speed and lower noise. All machines can be customized. It could be used to make the pipes in high speed. For this machine, we adopt middle plate weld machine frame to make sure machine working speed and steady.

Downpipe material can be divided into:

1. Metal pipes (such as cast iron pipes, colored aluminum pipes, copper pipes, colored steel pipes, etc.)

2. Plastic pipes (such as PVC pipes, etc.)

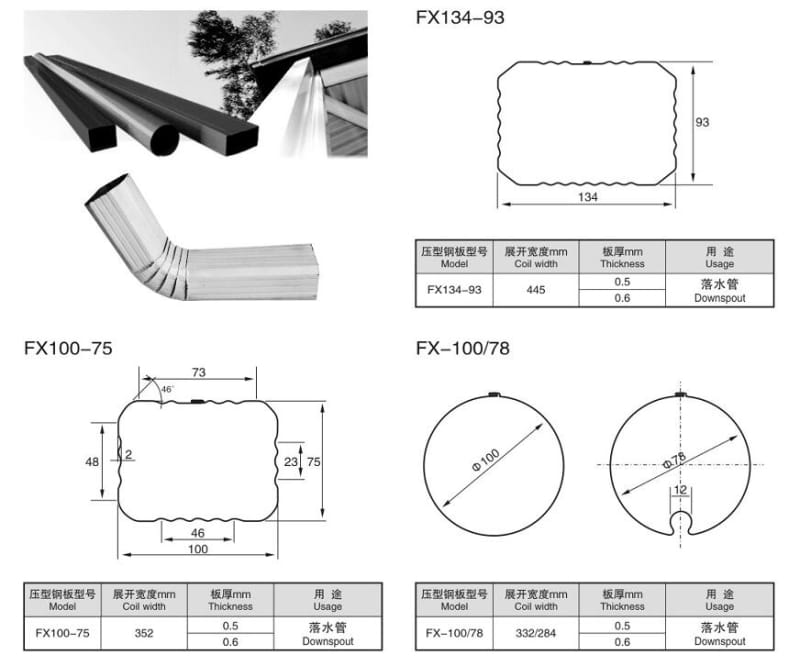

Here is the downspout profile drawing and dimensions for your reference. This interlock design don’t need any welding, it can save cost in machine production.

The Application of the finished product:

The Main Parameters of the machine:

Raw material: Galvanized steel Coils

Raw material thickness: 0.5-0.8mm

Coil width: 325mm

Yield Strength: 235Mpa

Quantity of forming rollers stations: 20-22

Diameter of forming rollers shafts: 60mm

Roll Forming Speed: 8-12m/min

Forming rollers material: No.45 steel, coated with chromed treatment

Cutter material: CR12 mould steel, with quenched treatment

Controlling system: PLC and Converter

If you are interested in, Please contact us by:

Whatsapp: +8618732780181

Email: bright@tgrollforming.com